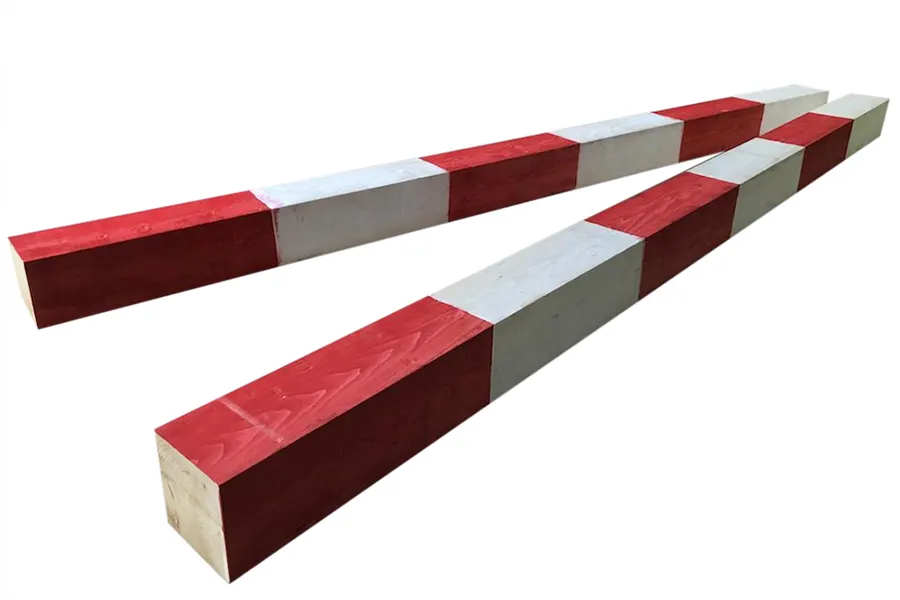

Hire - Road Plate

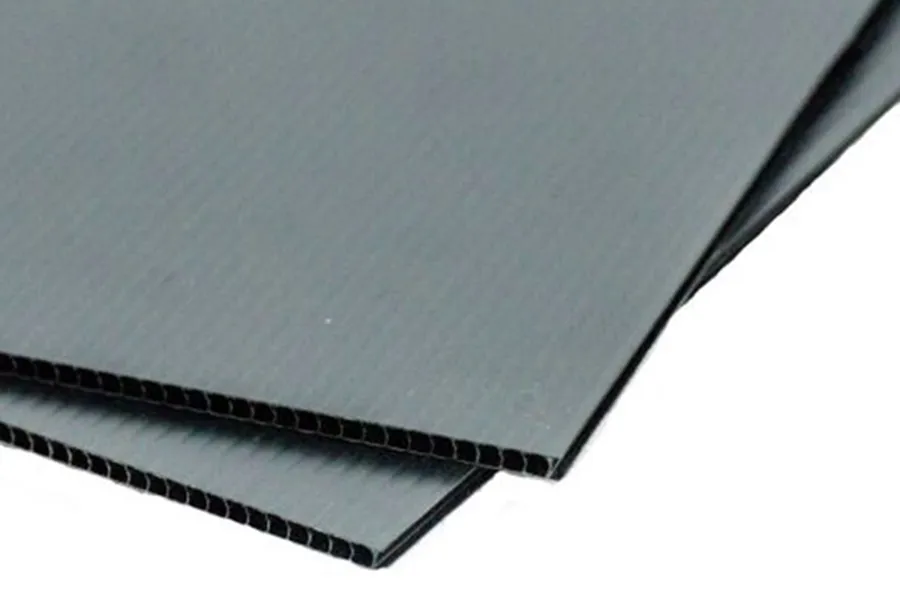

Road plates are normally used to cover temporary excavations in the highways network to assist with the flow of traffic when work is not being carried out.

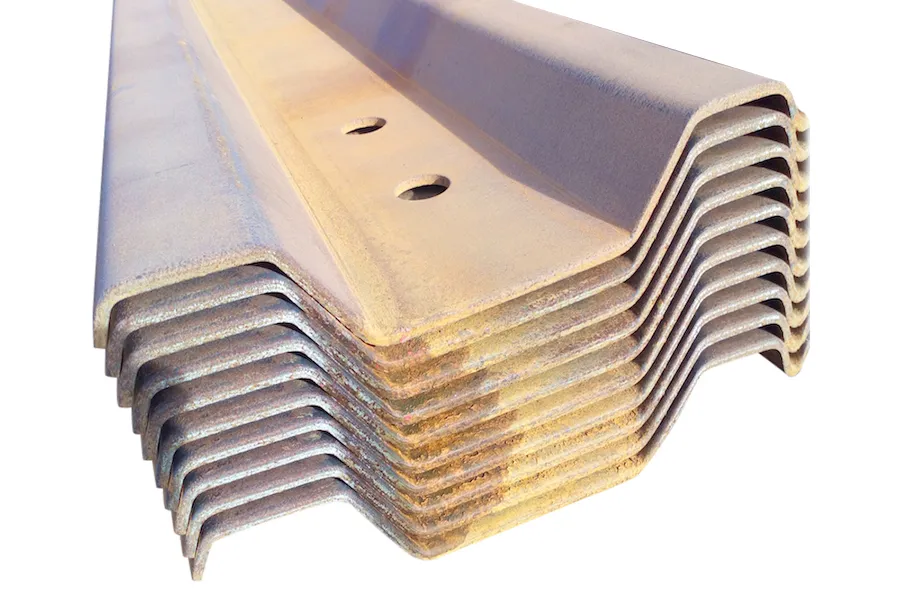

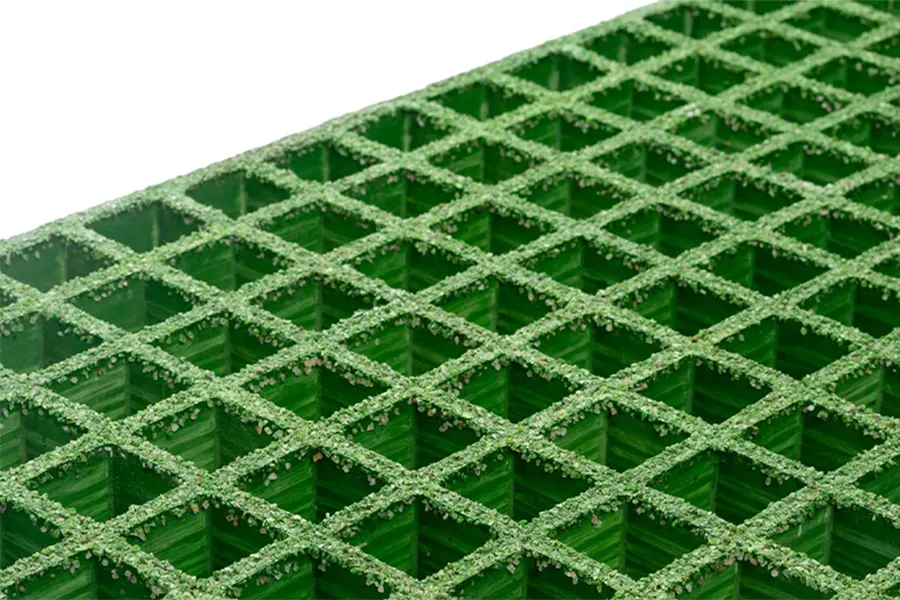

Our Anti-Skid Road Plates are made of mild steel and we supply them in a range of steel gauges in order to best suit your needs. These road plates are spread with resin over the plate and bauxite thrown on top of the resin. We use bauxite because it is the hardest natural stone available. There are cheaper aggregates available, but they are not strong enough for the job. It is also important to use resin rather than a simple paint. That is because paint is only strong enough to hold sand aggregates in place, it will not hold the bauxite.

All of our road plates are supplied with a hole in each of the four corners of the road plate, which are also known as road plate lifting eyes. This allows for the steel road plates to be chained for easier handling when placing and removing the road plates. The eyes on the road plate are approximately 60mm in dia and located 50mm from the edge of the steel road plate.

Please note that we do not supply any loading data on our range of road plates and that it is the customers responsibility to ensure that the road plate being used is suitable for the job intended. We suggest consulting a suitable professional, such as a structural engineer, before using a road plate.

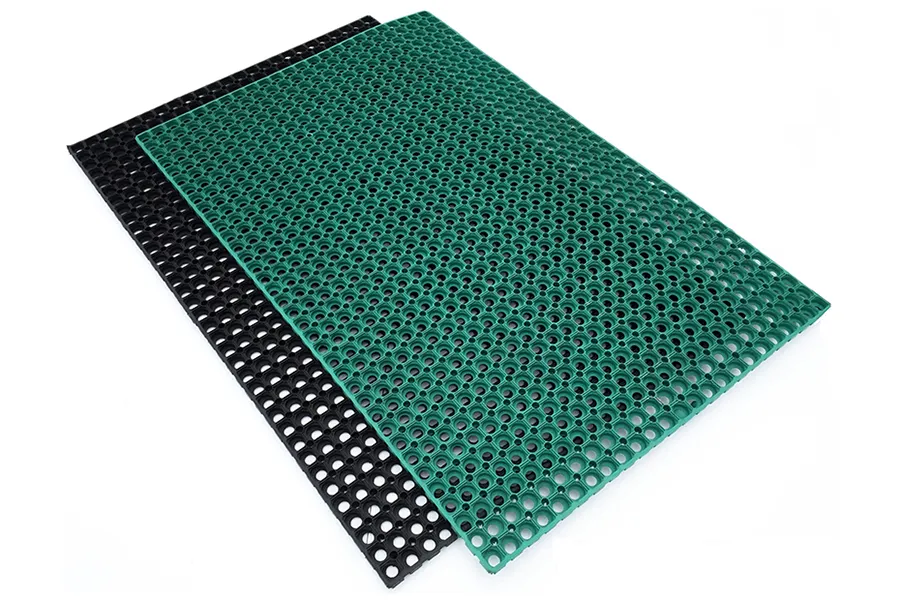

Also Available In Our Road Plate Category

- Anti-Slip Road Plates - include an anti-slip surface which uses a paint adhesive & aggregate.

- Plain Road Plates - a cost effective way of covering holes and trenches during ground works.

- Trench Cover Steel Plate - a range specially designed to cover narrow trenches.

**Due to the nature of this product sizes may differ slightly to that advertised - for an exact sized product please get in contact with one of our team before placing your order online

Need any help? Contact HERMEQ Today.

Contact our team via email sales@hermeq.nl or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

Manufacturing Anti-Skid Road Plate:

- Mild steel road plates firstly have four holes cut in each corner. These are most commonly cut using plasma cutting machines and are normally around 60-70mm in diameter and placed 50mm from the edges of the steel plate. These can be hand cut, but plasma cutters give a more professional and clean cut finish. Plasma cutting involves forcing a compressed gas (oxygen, air, inert and others depending on material being cut) through a focused nozzle at high speed toward the steel road plate. This is most common method of cutting thick steel road plates.

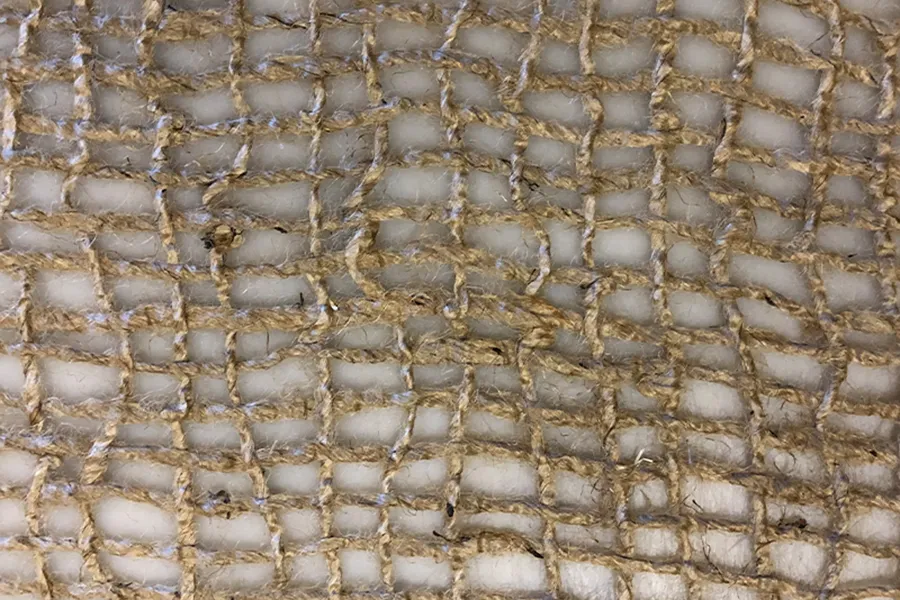

- You are then required to shot blast the steel road plate to SA2.5 – this means mill scale, rust and foreign particles are removed to the extent that only traces remain in the form of spots or stripes. The cleaned surface will now show varying shades of grey. If you do not shot blast the road plate then rust will remain, even if not visible to the naked eye, and over time this will result in the surface delaminating.

- Preparation of the road plate is vital. After shot blasting it is important to sweep the road plate and make sure that it is bone dry. Any moisture left on the surface before the anti-skid surface is applied will decrease the life span of the finished road plate.

- The plain road plate is now ready for an anti-skid surface to be applied. Step one of this process is to apply the prima & then leave the road plate to dry for 1 hour.

- After the plate has dried you can mix the resin (parts A & B) & spin for 2 minutes.

- Once the resin has been thoroughly mixed you can begin to spread the resin over the plate & throw bauxite on top of the resin. We use bauxite because it is the hardest natural stone available. There are cheaper aggregates available, but they are not strong enough for the job. It is also important to use resin rather than a simple paint. That is because paint is only strong enough to hold sand aggregates in place, it will not hold the bauxite.

- Finally leave the anti-skid road plates to dry for up to 4 hours and then you are ready to go.

English

English Dutch

Dutch Visit HERMEQ Ireland

Visit HERMEQ Ireland Visit HERMEQ France

Visit HERMEQ France Visit HERMEQ Germany

Visit HERMEQ Germany