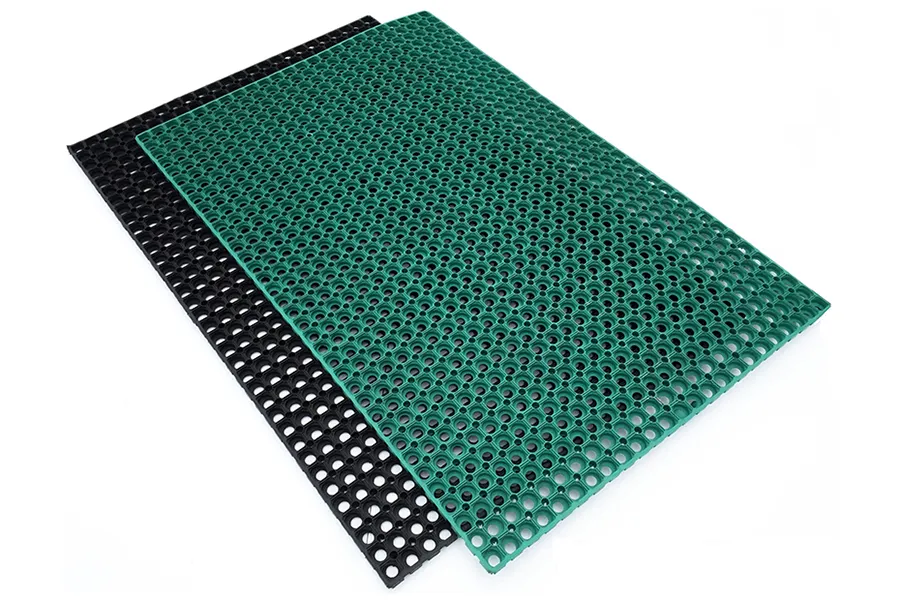

Rubber Floor Tiles

These strong, robust and versatile non-slip Recycled Rubber Floor Tiles are perfect to create a sleek, safe and secure outdoor work and play area that looks the part.

Commonly used as playground flooring, balcony flooring and roofing, these rubber mat squares carry a critical fall of up to 1 metre and are very easy to install using interlocking pegs or strong rubber adhesive.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

We have three different colours available for our Recycled Rubber Floor Tiles which are used as playground flooring, balcony flooring and roofing creating a safe and soft outdoor work and play areas. These rubber mat squares carry a critical fall of up to 1 metre making them perfect of low level outdoor playground flooring areas.

These Rubber Tiles are bought individually and 1m2 is comprised of 4 tiles. They provide a neat and stylish surface for your area and are easily installed onto solid and granular existing surfaces using the interlocking pegs provided or using a strong rubber adhesive.

Very easy to install and requiring zero maintenance, these wonderfully designed floor panels also allow for natural drainage to keep the surface below healthy – air, water and nutrients can reach the ground below which isn't always the case with alternatives on the market.

Interlocking Method (for a granular base):

- Prepare your sub-base (e.g. soil, sand) and ensure hardcore is level and well compacted – typically done using a vibration plate.

- Mark out edging system for your area where tiles will be installed to prevent outer edges moving. Can be made from concrete, plastic, timber or rubber.

- On top of prepared sub-base, lay the tiles one at a time starting in the corner and connecting each tile using interlocking pegs. Push interlocking pegs halfway into pre-drilled holes and then push the next tile onto two of the pegs sticking out ensuring they are tightly pressed together with no visible gaps. Repeat this one row at a time until the entire area has been filled.

- Polyurethane adhesive can be used in the joints of each tile are fixed sufficiently to ensure total integrity.

Non-Interlocking Method (for a solid base):

- Prepare sub-base, concrete or tarmac and ensure concrete is sealed, fully cured, crack and gap-free. Ensure tarmac is hard, flat, dry, fully cured over 30 days and free of all impurities.

- Mark out your area where tiles will be installed and install edging system around perimeter of where tiles will be laid to prevent outer edges moving – made from concrete, plastic, timber or rubber.

- Using appropriate polyurethane adhesive, apply 4 rows of adhesive to underside of tile in a 3mm bead. Secure tile in place and ensure there is 3-4mm joint between each tile that can be filled with sand or another fine-grade, porous medium. Repeat process until area has been filled and tiles are butting with edging installed earlier.

Our non-slip Rubber Square Mats can also be cleaned using warm soapy water and left to dry when they become unclean and grimy over time.

Simply contact our sales team to have a conversation about your requirements today.

Specifications

Tile Dimensions: 500mm x 500mm

Tile Depth: 30mm

Tile Weight: 4.8 kg

Tiles Required per m2: 4 tiles

Material: Recycled SBR Rubber Granulate

Compliant with BS EN 1177

HERMEQ stock a wide range of Ground Mats, Bog Mats, Trench Covers & Road Plates conforming to all required safety specifications and regulations.

Need any help? Contact HERMEQ Today.

Contact our team via email sales@hermeq.nl or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

English

English Dutch

Dutch Visit HERMEQ Ireland

Visit HERMEQ Ireland Visit HERMEQ France

Visit HERMEQ France Visit HERMEQ DACH

Visit HERMEQ DACH Visit HERMEQ USA

Visit HERMEQ USA