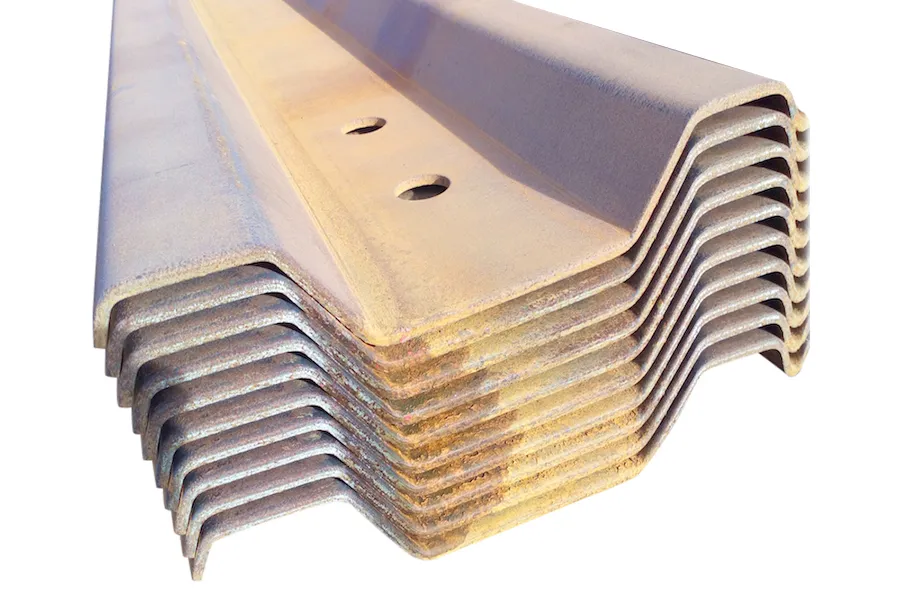

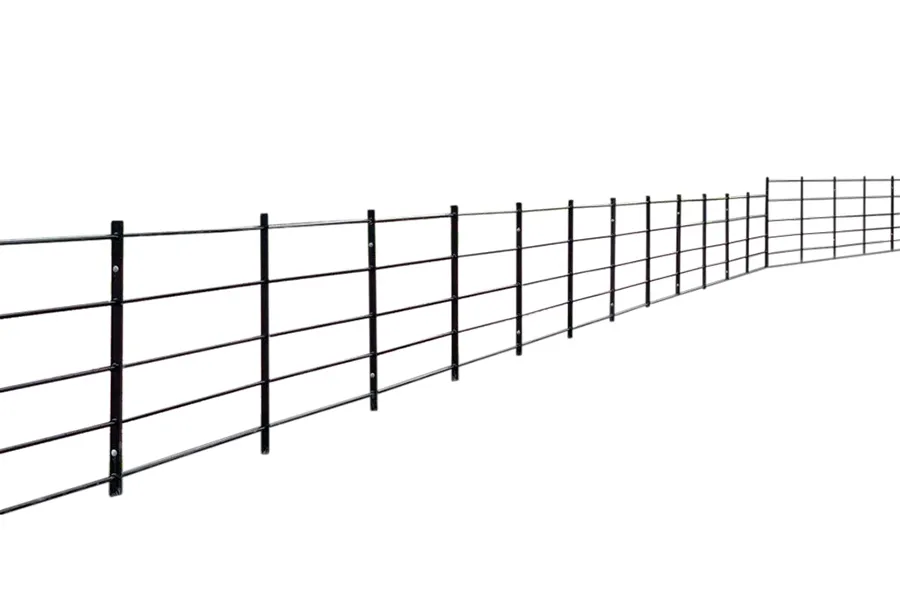

GRP Shoring Rail

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

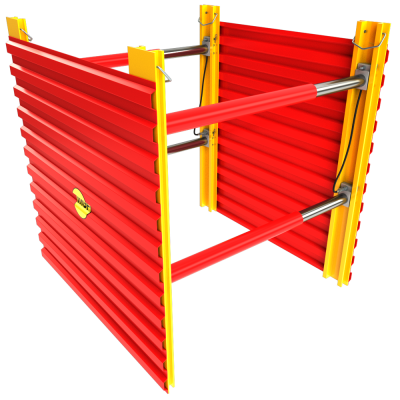

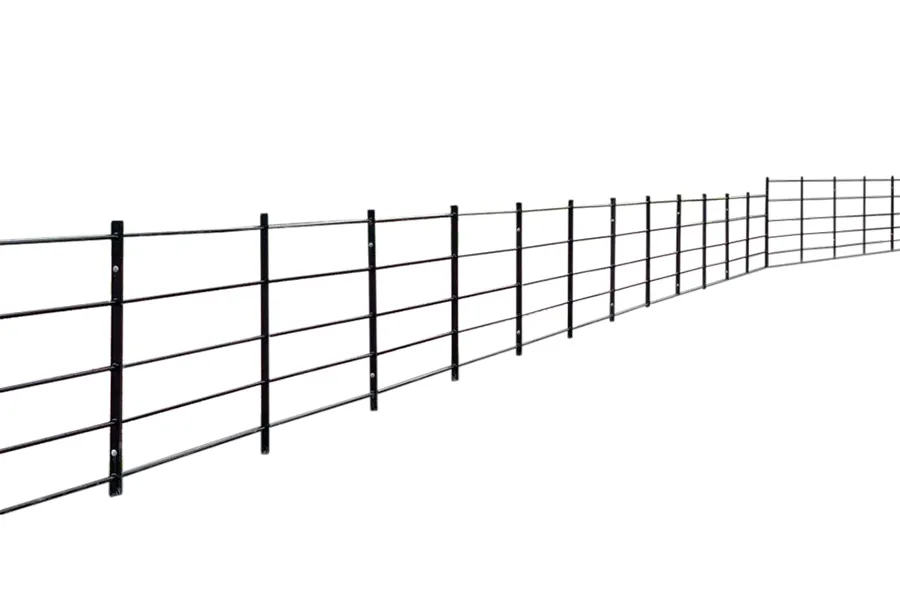

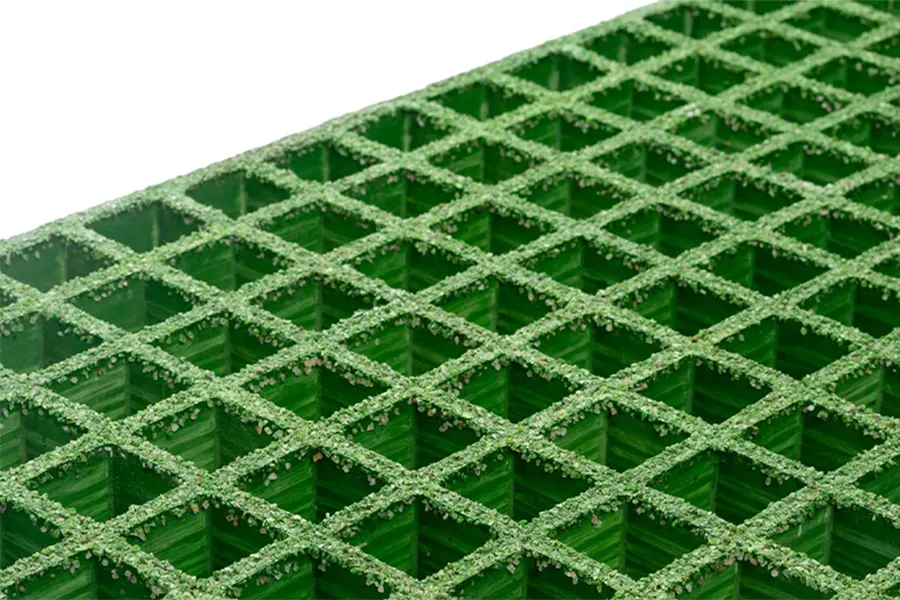

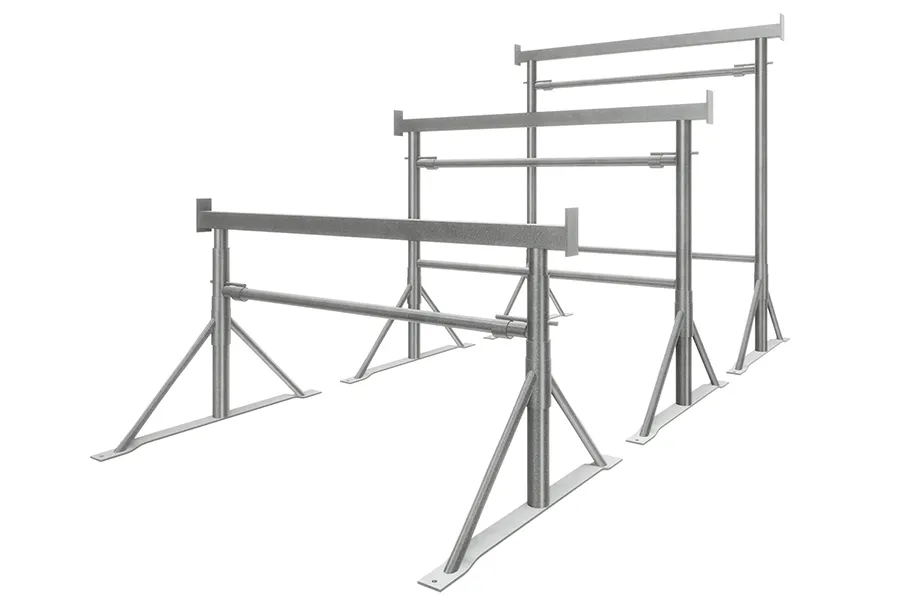

GRP Shoring has been specifically designed to act as a light-weight trench shoring system for excavations up to 2.0m deep and 2.0m wide. Manufactured from GRP (Glass Reinforced Plastic) it is non-conductive & fire retardant to ASTM E84 Class 1. Due to its lightweight design our GRP showing system can be transported on much smaller vehicles & installed by hand.

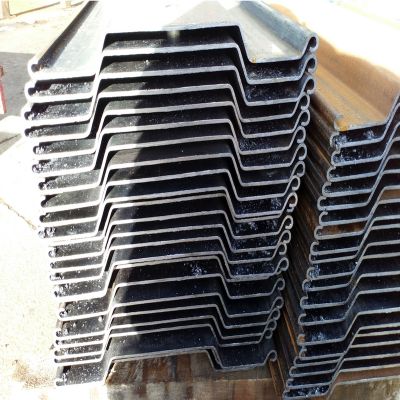

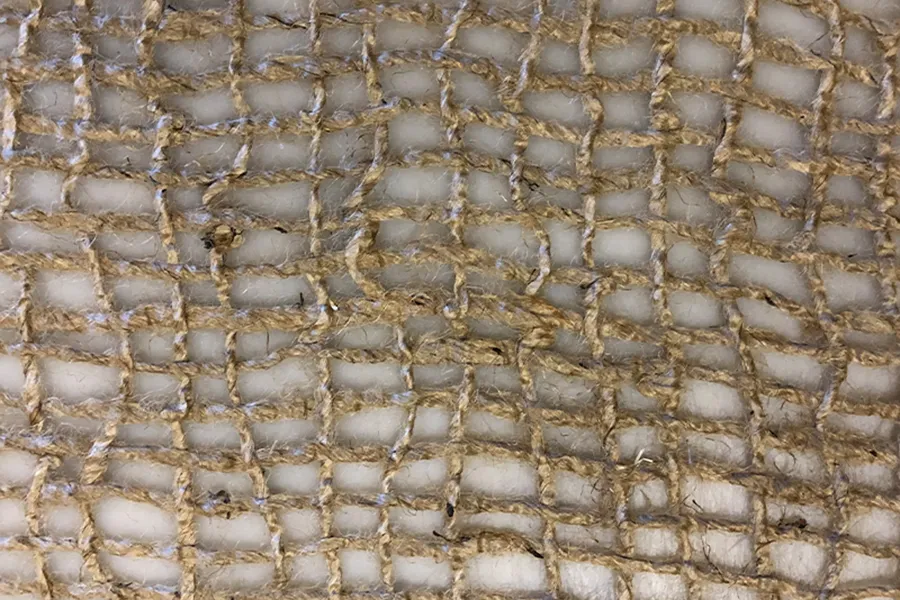

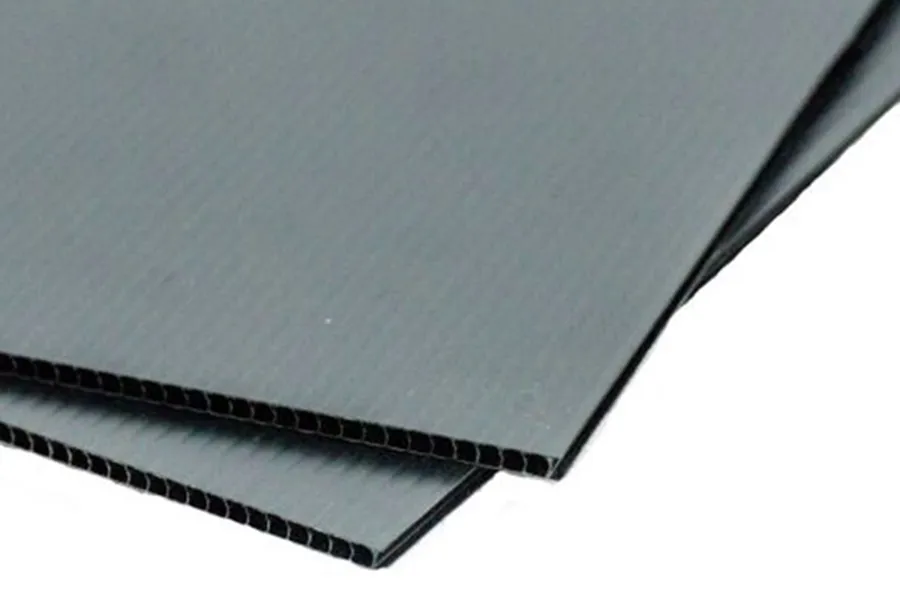

The GRP shoring rails come with option of a 0.5m wide bonded backing board, although loose lagging boards are also available if required. Backing boards are used when the ground needs more support as they give you a larger surface area for your GRP shoring system against the trench wall.

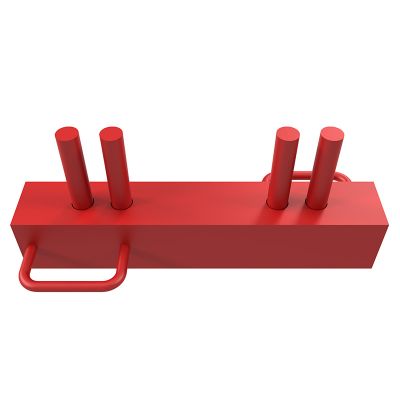

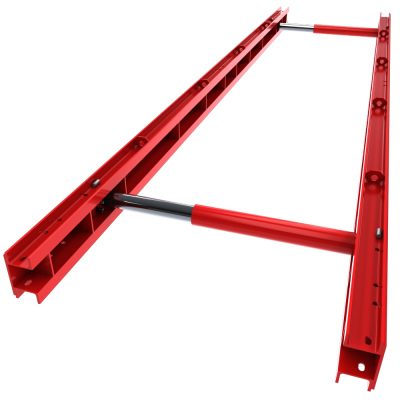

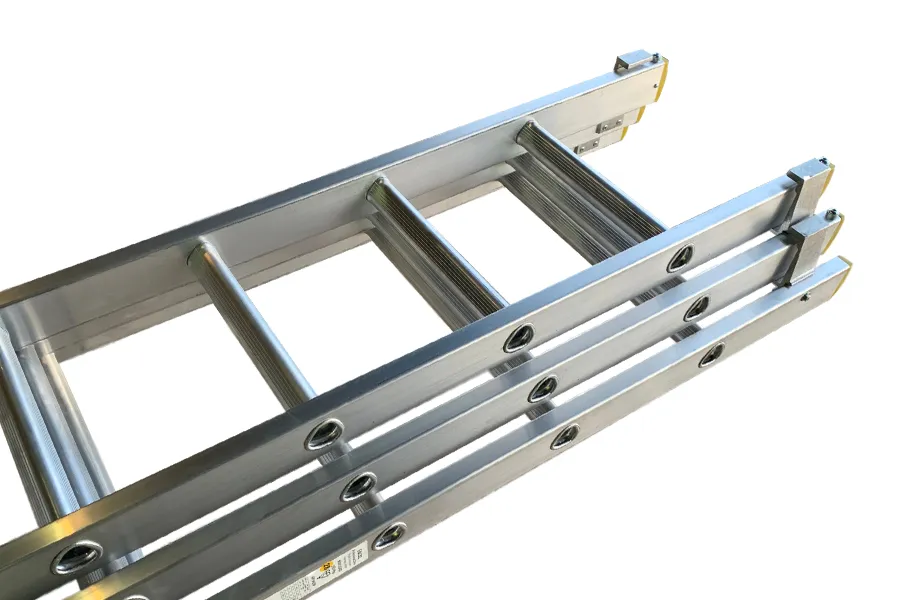

Hydraulic struts are positioned between the shoring rails & the whole system is assembled before being placed into the trench. Hydraulic struts allow you to support trench widths ranging from 570mm to 1420mm.

Once the GRP shoring system is placed into the trench these Hydraulic struts are pumped until the GRP panels push firmly against the trench excavation walls, continue to pressurise until the bucket pump registers between 450 - 750psi & there is no sign of pressure loss.

The GRP shoring rails should be installed no more than 1.5m apart from one another, depending on your excavation design. Beyond 1.0m depth, operatives should only access and work in the trench between pressurised units & it is recommended installing a minimum of three units if there is adequate space. You should never enter via ends/faces of an unsupported excavation at greater depths.

Need any help? Contact HERMEQ Today.

Contact our team via email sales@hermeq.nl or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

English

English Dutch

Dutch Visit HERMEQ Ireland

Visit HERMEQ Ireland Visit HERMEQ France

Visit HERMEQ France Visit HERMEQ DACH

Visit HERMEQ DACH Visit HERMEQ USA

Visit HERMEQ USA