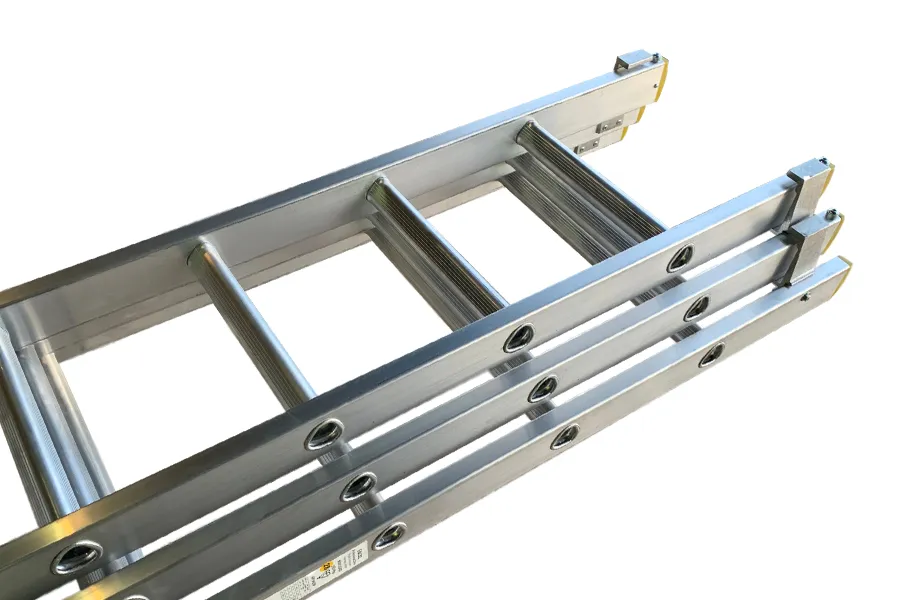

Low Profile Extending Jib Attachment

Low Profile Extending Jib Attachments are commonly used to lift awkward loads in areas where workspace is limited with its impressive choice of ten different loading positions.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

Designed to exceed the limitations of the standard Low Profile Jib, the Low Profile Extending Jib Attachment doubles the number of loading positions with an incredible ten different loading positions to choose from. An ingeniously well-designed forklift attachment, the Low Profile Extending Jib makes the task of relocating difficult loads safer, simpler, and quicker in warehouse and construction environments.

The presence of hook and shackles makes the process even smoother with the two hook and shackles capable of adding support to intended loads.

The ten different loading positions allow for a large spectrum of different loading options with loading point centres ranging from 500 mm at centre to 3000 mm at centre.

Storage and transportation of the attachment have also been a key consideration during the manufacturing process with four-way entry fork pockets making each task slicker.

Suitable for use with most forklift trucks and telehandlers, the Extending Jib Attachment has a maximum fork section of 150 mm x 50 mm at 281 mm centres.

Ensuring the safety and security of the Jib while in use, the inclusion of zinc-plated heel pins guarantees that once correctly secured, the Extending Low Profile Jib will perform as expected, safe from breaking free.

Following on with themes of the health of safety, even the colour of the Extending Forklift Jib has been taken into consideration, with a bright orange painted finish used to provide high levels of visibility for extra workplace safety.

Before using the Telehandler Extending Jib, a full risk assessment should be conducted with any damages or concerns being reported and repaired immediately.

To begin using the Low Extending Jib, the forks of the forklift truck should be positioned to the appropriate distance in relation to the corresponding forklift pockets and heel pins should be removed from the Jib.

Once these tasks have been completed, the forklift or telehandler can be driven into the forklift pockets of the Jib before the heel pins are reinserted into the appropriate holes using the safety lynch pin. The swivel hook and shackle should then be positioned at the appropriate lifting point before being securely tightened into place. The extending boom of the Expandable Jib can be positioned by removing the "T" Bar locating pin and pushing or pulling on the handle before replacing the "T" Bar once the corresponding holes have been aligned.

In order to use the Low Profile Extending Jib correctly and to enhance the product life of the jib, regular maintenance procedures should be followed weekly.

The general condition of the Jib should be taken into consideration with weld points, fork pockets, heel pins, extending boom, and swivel hook and shackle components areas checked regularly. As mentioned previously, if any damages or concerns are found during these checks, they should be reported and repaired immediately before use. General surface rusting is a common issue with all forklift attachments and can be treated easily with paint, primers, and prohibitory inhibitors.

The Extendable Low Profile Jib is certified for up to six months from the date of manufacture. Once this date has passed it becomes the responsibility of the customer to have the product inspected by the relevant authority.

Vehicles and attachments should always be checked before use to ensure they are capable of lifting the intended load and that the Jib has been set to the correct lifting point in order to prevent accidents.

Heel pins and moveable components should always be checked to ensure they are secure and being used in the correct manner before use.

Angular lifts, sideways lifts, and shock loading should always be avoided as the Jib Attachment has not been designed to hold the set maximum load capacities in that manner.

A wide range of Low Profile Extending Jibs are available online via HERMEQ and can be purchased online or through discussion with our sales team.

Delivery:

Delivery times can vary and are stock-dependent. Average delivery times are between 24 hours and 5 working days.

If you have any questions please call us on 0121 725 2338.

HERMEQ stock a wide-range of Scaffolding Equipment, Building Supplies, Lifting Equipment & PPE conforming to all required safety specifications and regulations. Lightweight, easy to use & made with premium quality materials in Europe!

Need any help? Contact HERMEQ Today.

Contact our team via email sales@hermeq.nl or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

Low Profile Extending Jib 1000 kg

- Max load capacity at 500 mm: 1000 kg

- Max load capacity at 1000 mm: 700 kg

- Max load capacity at 1250 mm: 500 kg

- Max load capacity at 1500 mm: 400 kg

- Max load capacity at 1750 mm: 250 kg

- Max load capacity at 2000 mm: 260 kg

- Max load capacity at 2250 mm: 230 kg

- Max load capacity at 2500 mm: 190 kg

- Max load capacity at 2750 mm: 150 kg

- Max load capacity at 3000 mm: 100 kg

- Weight: 95 kg

- C of G: 750 mm - 1010 mm

Low Profile Extending Jib 1500 kg

- Max load capacity at 500 mm: 1500 kg

- Max load capacity at 1000 mm: 1100 kg

- Max load capacity at 1250 mm: 900 kg

- Max load capacity at 1500 mm: 650 kg

- Max load capacity at 1750 mm: 450 kg

- Max load capacity at 2000 mm: 400 kg

- Max load capacity at 2250 mm: 350 kg

- Max load capacity at 2500 mm: 300 kg

- Max load capacity at 2750 mm: 220 kg

- Max load capacity at 3000 mm: 150 kg

- Weight: 100 kg

- C of G: 750 mm - 1010 mm

Low Profile Extending Jib 2000 kg

- Max load capacity at 500 mm: 2000 kg

- Max load capacity at 1000 mm: 1600 kg

- Max load capacity at 1250 mm: 1200 kg

- Max load capacity at 1500 mm: 900 kg

- Max load capacity at 1750 mm: 600 kg

- Max load capacity at 2000 mm: 500 kg

- Max load capacity at 2250 mm: 400 kg

- Max load capacity at 2500 mm: 350 kg

- Max load capacity at 2750 mm: 280 kg

- Max load capacity at 3000 mm: 200 kg

- Weight: 109 kg

- C of G: 750 mm - 1010 mm

- Low Profile Extending Jib 3000 kg

- Max load capacity at 500 mm: 3000 kg

- Max load capacity at 1000 mm: 2100 kg

- Max load capacity at 1250 mm: 1600 kg

- Max load capacity at 1500 mm: 1100 kg

- Max load capacity at 1750 mm: 850 kg

- Max load capacity at 2000 mm: 715 kg

- Max load capacity at 2250 mm: 620 kg

- Max load capacity at 2500 mm: 440 kg

- Max load capacity at 2750 mm: 320 kg

- Max load capacity at 3000 mm: 250 kg

- Weight: 127 kg

- C of G: 750 mm - 1010 mm

- Low Profile Extending Jib 4000 kg

- Max load capacity at 500 mm: 4000 kg

- Max load capacity at 1000 mm: 3200 kg

- Max load capacity at 1250 mm: 2500 kg

- Max load capacity at 1500 mm: 1900 kg

- Max load capacity at 1750 mm: 1100 kg

- Max load capacity at 2000 mm: 975 kg

- Max load capacity at 2250 mm: 850 kg

- Max load capacity at 2500 mm: 650 kg

- Max load capacity at 2750 mm: 500 kg

- Max load capacity at 3000 mm: 400 kg

- Weight: 138 kg

- C of G: 750 mm - 1010 mm

English

English Dutch

Dutch Visit HERMEQ Ireland

Visit HERMEQ Ireland Visit HERMEQ France

Visit HERMEQ France Visit HERMEQ DACH

Visit HERMEQ DACH Visit HERMEQ USA

Visit HERMEQ USA