Fork Mounted Magnet

The Fork Lift Magnet is a magnetic sweeper designed for use on the forks of a forklift truck.

Quickest Available Delivery: Quickest Available Delivery: 5 Day Delivery

The Fork Lift Magnet is one of the most ingenious yet simple pieces of equipment available for industrial use. As the name suggests, the Fork Lift Magnet does exactly what it says on the tin.

Used to collect metal debris, the Forklift Magnet is attached to the forks of the forklift and uses the magnet to pick up the debris.

Suitable for use in numerous locations, the Forklift-Magnet is commonly used in construction, manufacturing, and warehousing industries on factory floors, car parks, and construction sites.

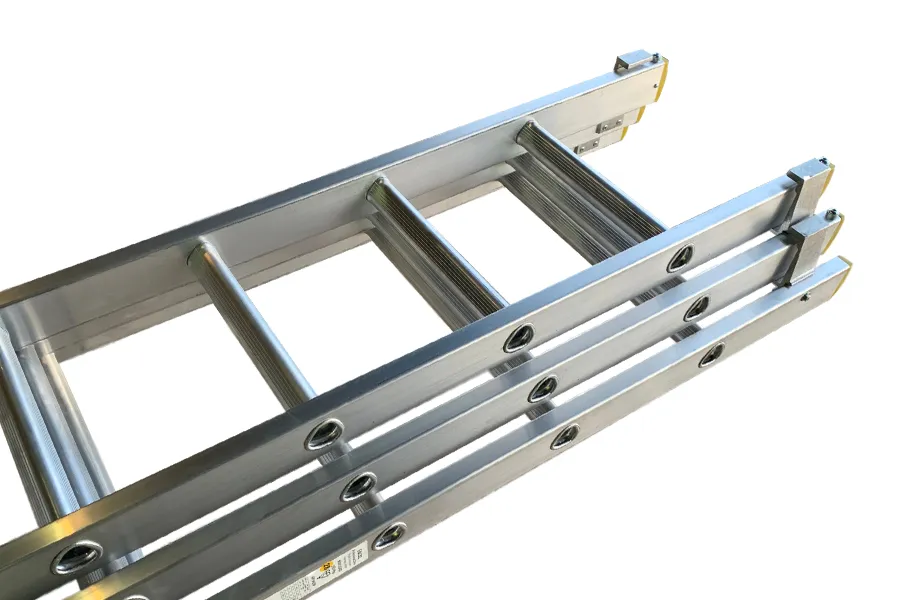

The installation and use of the Fork Lift Magnet are pretty straightforward and time-efficient. In order to begin the setup process, the forks of the forklift truck must be positioned to the required distance to fit the fork pockets on the Forklift Magnetic Sweeper.

(The maximum fork section applicable is 150 x 60 mm at 683 mm centres.)

The driver of the forklift truck must then carefully drive the forks into the pockets of the Fork Lift Magnet before the thumbscrews are tightened, ensuring the magnet is tightly fastened to the forks.

This completes the installation of the Fork Mounted Magnet. It's really that simple!

When using the Magnetic Sweeper, begin by positioning the Fork Lift Magnet 75 to 100 mm above the level floor and drive at a slow and steady speed for effective steel debris collection.

Once finished or the maximum amount of debris has been collected, simply raise the Fork Lift Magnet and scrape the bottom of the magnet to remove the collected metal debris.

In order to ensure the maximum efficiency of the Fork Lift Magnet and extend the expected product life as much as possible regular the following maintenance checks should be regularly conducted:

The magnet should be checked for general wear and tear and damages that could arise from the industrial environment in which it is being used. Special attention should be given to all of the weld points and the thumbscrew attachments.

If the Fork Mounted Magnet shows any signs of damage or incapability of performing as intended, report and fix immediately before use.

The Magnetic Sweeper is certified for six months from the date of manufacture. After these six months are up, the responsibility of maintaining rests upon the customer who must ensure they have the Magnet retested by an approved testing facility.

As with any heavy-duty equipment and working environment, the person or persons using the Magnet and forklift truck must always complete a risk assessment and make sure that they use the equipment safely and responsibly.

Before attempting to affix the Fork-Lift-Magnet to the forklift ensure the forks of the forklift are capable of safely lifting the weight of the magnet.

When using the Fork Lift Magnet, be sure the thumbscrews are tightened properly to prevent accidents or injuries.

Once the work has been completed and it is time to remove the collected debris, be sure to wear the correct protective clothing such as safety goggles and safety gloves to avoid any risks presented by steel shards.

Specifications

Fork Lift Magnet 1200 mm:

- Width: 1200 mm

- C of G: 55 mm

- Weight: 52 kg

Fork Lift Magnet 1800 mm:

- Width: 1800 mm

- C of G: 55 mm

- Weight: 78 kg

Delivery

Delivery times can vary and are stock dependant. Average delivery times are between 24 hours and 5 working days.

HERMEQ stock a wide-range of Scaffolding Equipment, Building Supplies, Lifting Equipment & PPE conforming to all required safety specifications and regulations. Lightweight, easy to use & made with premium quality materials in Europe!

Need any help? Contact HERMEQ Today.

Contact our team via email sales@hermeq.nl or use our live chat feature between 8:00am & 17:00pm for help discovering our range.

English

English Dutch

Dutch Visit HERMEQ Ireland

Visit HERMEQ Ireland Visit HERMEQ France

Visit HERMEQ France Visit HERMEQ DACH

Visit HERMEQ DACH Visit HERMEQ USA

Visit HERMEQ USA