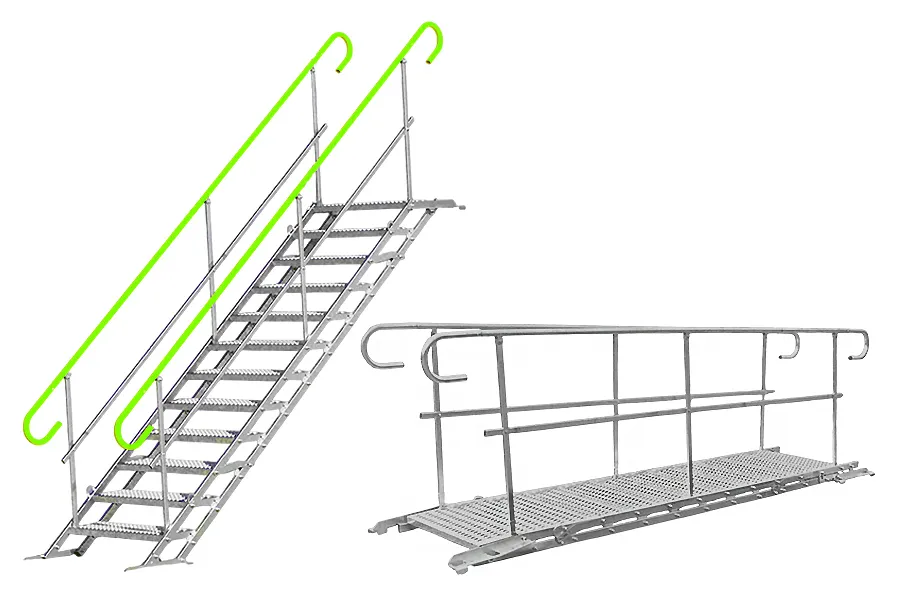

Lasthaken Bulkzak

Lasthaken voor bulkzakken vergemakkelijken het tillen van volle of gedeeltelijk gevulde bulkzakken en zandzakken.

Snelst mogelijke bezorgtijd: Snelst mogelijke bezorgtijd: Tot 5 werkdagen

Lasthaken voor bulkzakken zijn eenvoudige, doch effectieve middelen om zware of omvangrijke zakken snel en veilig te verplaatsen met standaard vorkheftrucks of verreikers. Deze zijn slim ontworpen voor gebruiksgemak en duurzaamheid, en verminderen het risico op beschadiging van de zakken door hun uitgebreide lastcentrum en ingebouwde vorkzakken. Veel gebruikt in magazijnen en de bouw, hebben deze hulpstukken voor zakdragers vele toepassingen die tijd en geld besparen voor de gebruiker.

Om een lasthaak voor bulkzakken te gebruiken, begin met een grondige risicobeoordeling van de apparatuur en de omgeving. Nadat de juiste veiligheidscontroles zijn uitgevoerd en het veilig is bevonden, kan de lasthaak op de vorkheftruck of verreiker worden gemonteerd.

Begin met het monteren van het hulpstuk op de vorken van het gekozen voertuig door de vorken op de vereiste afstand uit elkaar te zetten die overeenkomt met de zakken van de vorkheftruck van de steenzaklift. Verwijder de verzinkte hiel pinnen van de zakdrager voordat je de vorken in de vorkzakken van het hulpstuk rijdt. Zodra de vorken correct zijn ingevoegd in de vorkzakken, plaats je de hiel pinnen terug achter de hiel van de vork en gebruik je de veiligheidsvergrendeling in het juiste gat om op zijn plaats te zekeren. De lasthaak voor bulkzakken is nu klaar voor gebruik.

De hijsbanden van de te tillen zak moeten over de vier hijsogen aan de zakdrager worden gehangen, zorg ervoor dat ze correct zijn geplaatst voordat je de vorkheftruck gebruikt om de verplaatsing van de lading te navigeren en te controleren.

Regelmatig onderhoud van de lasthaak voor bulkzakken moet worden uitgevoerd om de veiligheid en efficiëntie van het hulpstuk te waarborgen, en om eventuele ongevallen of verwondingen die kunnen worden veroorzaakt door het niet volgen van de juiste onderhoudsprocedures te voorkomen.

Wekelijkse controles moeten de volgende gebieden omvatten:

Alle laspunten, vorkzakken, hiel pin bevestigingen en beschadigde of versleten onderdelen moeten worden gecontroleerd op algemene slijtage, waarbij eventuele schades onmiddellijk worden gemeld en gerepareerd.

Zoals bij de meeste vorkheftruck hulpstukken, kan algemene oppervlakteroest een probleem worden en moet regelmatig worden behandeld met verf, primers en eigen roestwerende middelen.

De lasthaak voor bulkzakken is gecertificeerd voor gebruik tot zes maanden vanaf de fabricagedatum. Na deze datum is het de verantwoordelijkheid van de klant om het hulpstuk opnieuw te laten testen door de juiste testautoriteit.

Om de vorkgemonteerde lasthaak voor bulkzakken te gebruiken terwijl je gezondheids- en veiligheidsprocedures naleeft, moeten de volgende taken altijd worden voltooid:

De apparatuur en omgeving die worden gebruikt, moeten altijd worden gecontroleerd op geschiktheid, waarbij zorgvuldig wordt gelet op de staat van oppervlakken en apparatuur.

De maximale belastingscapaciteit van alle gebruikte apparatuur en voertuigen mag nooit worden overschreden, aangezien ze niet zijn ontworpen om grotere ladingen te dragen en dit zal de kans op ongevallen aanzienlijk verhogen.

De lasthaak voor bulkzakken en hiel pinnen moeten altijd worden gecontroleerd om er zeker van te zijn dat ze correct en veilig zijn bevestigd tijdens gebruik. Het niet doen kan ervoor zorgen dat de lading tijdens gebruik losraakt, wat kan leiden tot ernstige ongevallen of verwondingen.

Terwijl de hiel pinnen stevig moeten worden vastgezet tijdens het tillen van ladingen, moeten de hiel pinnen NIET op hun plaats zijn terwijl de vorken van het voertuig de vorkzakken van de zakdrager binnengaan.

Bij het tillen van ladingen moet de lading verticaal worden opgetild en moeten hoekige liften te allen tijde worden vermeden. Het hulpstuk mag alleen worden gebruikt met een voertuig dat een geschikte snelheid en richting handhaaft om te voorkomen dat de lading gaat slingeren. De mast moet ook te allen tijde in de verticale positie blijven.

De lasthaak voor bulkzakken mag nooit worden blootgesteld aan schokbelasting onder welke omstandigheden dan ook, aangezien deze niet is ontworpen om gewicht op die manier te tillen en het doen ervan verhoogt de kans op ongevallen en schade aan het hulpstuk.

Levering:

Leveringstijden kunnen variëren en zijn afhankelijk van de voorraad. Gemiddelde leveringstijden liggen tussen 24 uur en 5 werkdagen.

Als u vragen heeft, bel ons dan op 0121 725 2338.

HERMEQ heeft een breed assortiment aan Steigeruitrusting, Bouwmaterialen, Hefapparatuur & PBM die voldoen aan alle vereiste veiligheidsspecificaties en -voorschriften. Lichtgewicht, eenvoudig te gebruiken en gemaakt van hoogwaardige materialen in het VK!

Hulp nodig? Neem vandaag nog contact op met HERMEQ.

Neem contact op met ons team via telefoon 0121 725 2338, e-mail verkoop@hermeq.nl of gebruik onze live chat-functie tussen 8:00 en 17:00 uur voor hulp bij het ontdekken van ons assortiment.

Heb je nog hulp nodig? Neem dan contact op met HERMEQ.

Neem contact op door te e-mailen naar sales@hermeq.nl of bel ons tussen 9:00 en 17:00 op +31 202417011

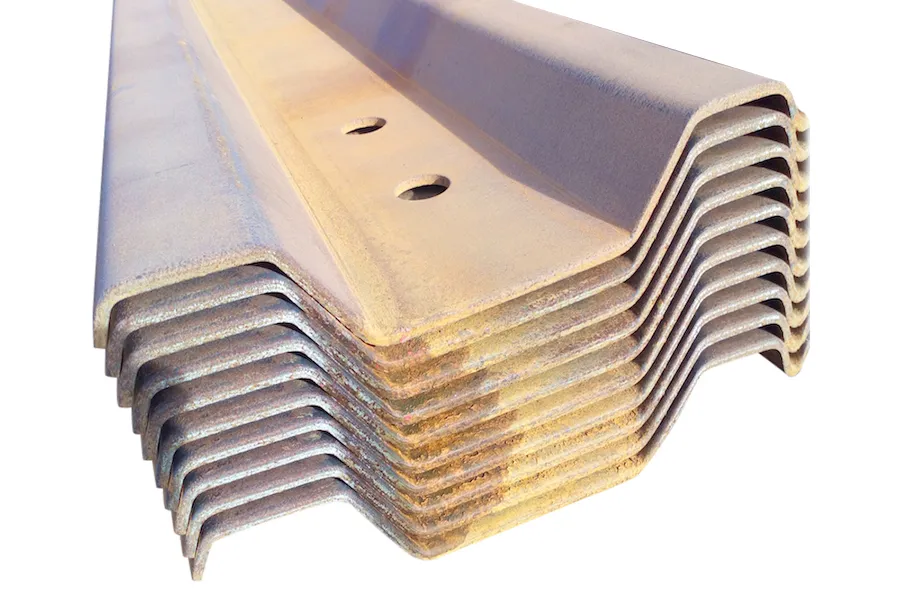

Lasthaak voor Bulkzakken 1000 kg

Maximale belastingscapaciteit: 1000 kg

Lastcentrum: 885 mm

Maximale vork: 125 mm x 50 mm

Vork spreiding: 600 mm

Gewicht: 72 kg

Lasthaak voor Bulkzakken 2000 kg

Maximale belastingscapaciteit: 2000 kg

Lastcentrum: 885 mm

Maximale vork: 125 mm x 50 mm

Vork spreiding: 600 mm

Gewicht: 72 kg

Nederlands

Nederlands Engels

Engels Bezoek HERMEQ Irlande

Bezoek HERMEQ Irlande Bezoek HERMEQ Frankrijk

Bezoek HERMEQ Frankrijk Bezoek HERMEQ DACH

Bezoek HERMEQ DACH Bezoek HERMEQ VS

Bezoek HERMEQ VS