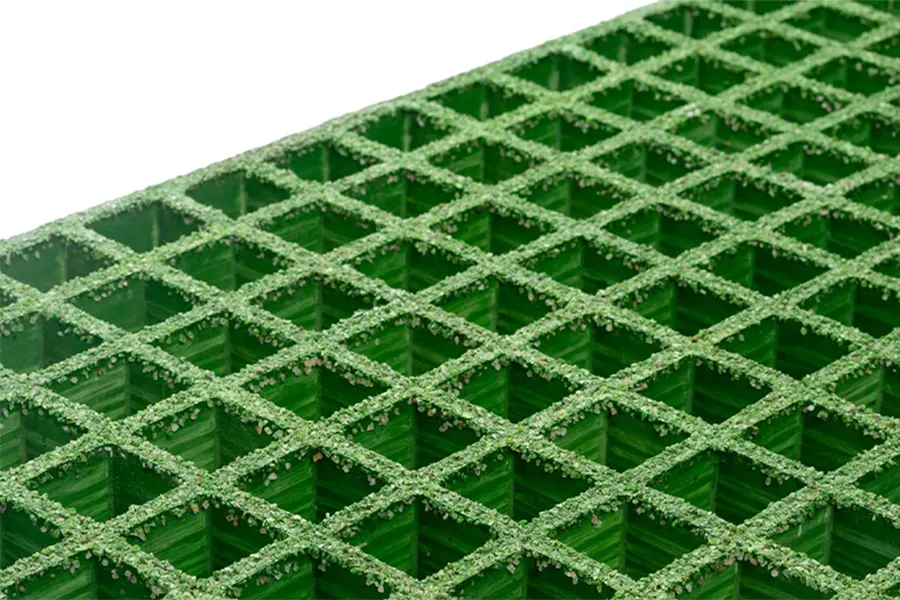

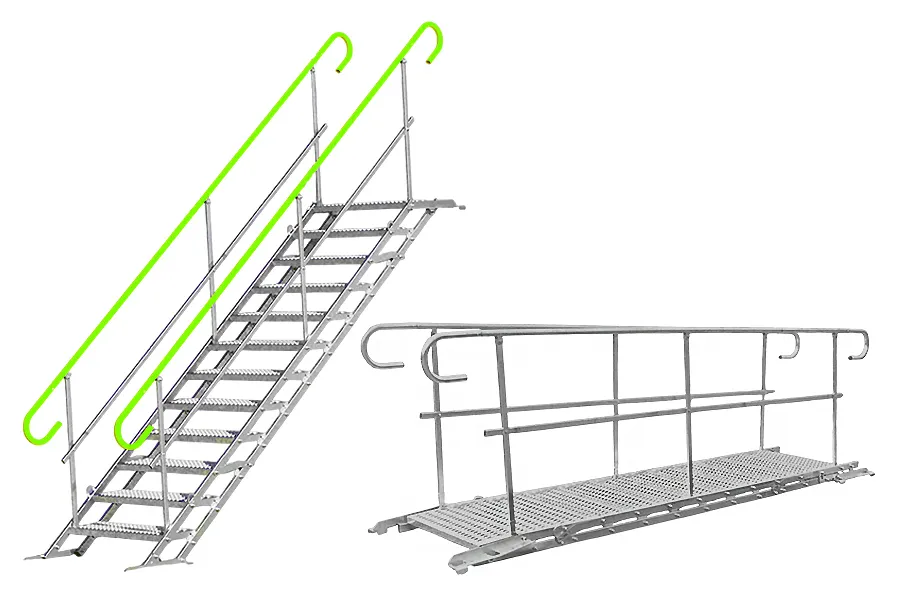

GRP Looprooster

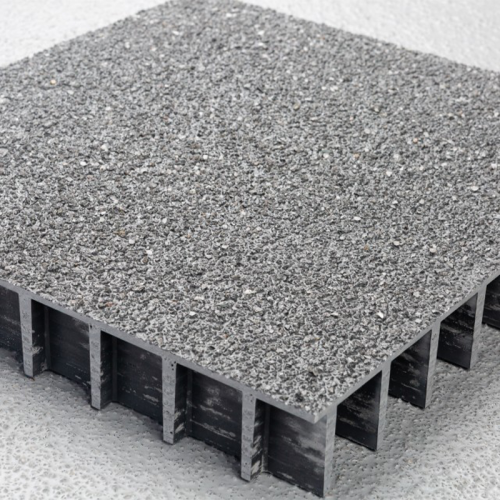

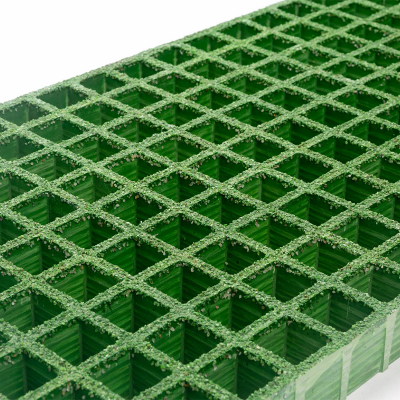

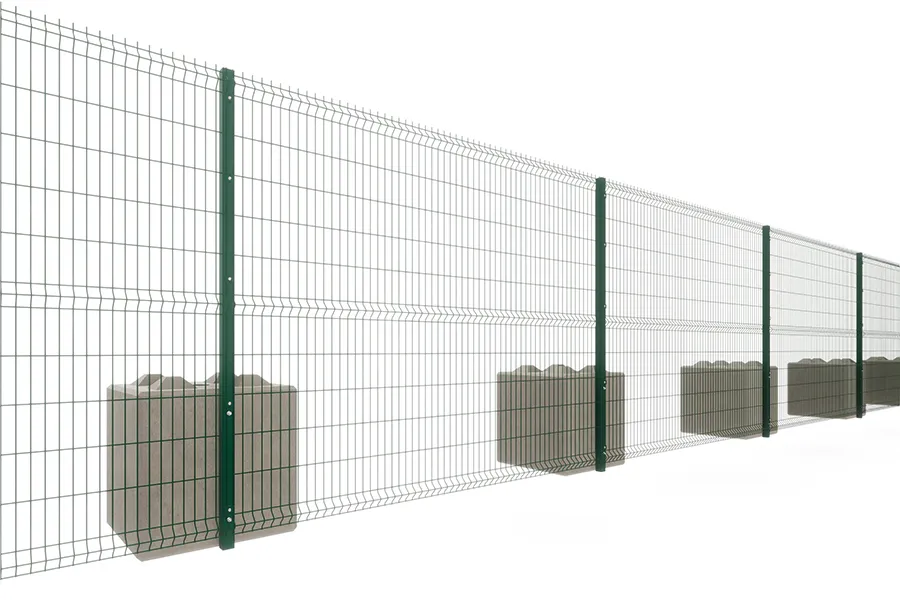

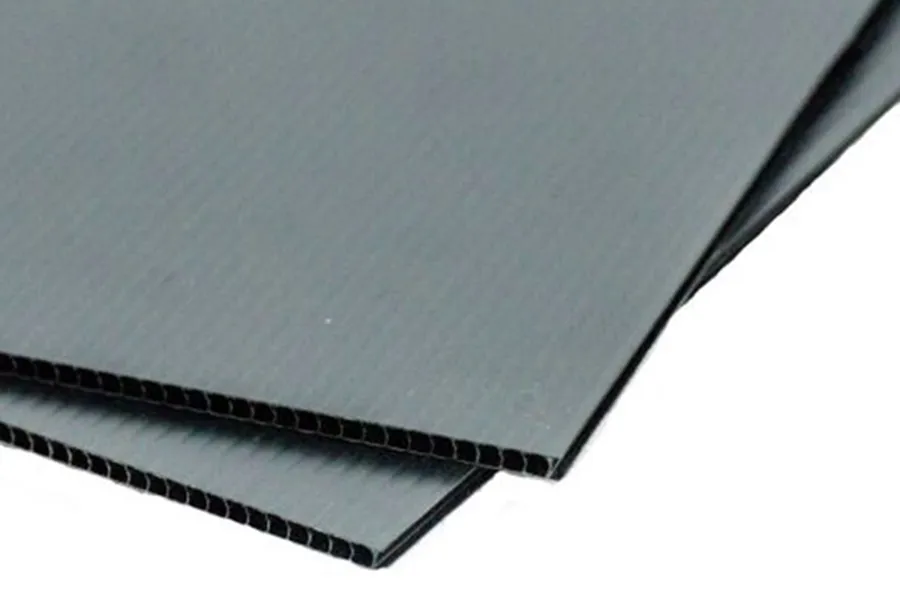

GRP Looprooster is een gegoten, lichtgewicht en duurzame gesloten bovenvloeroplossing die wordt gebruikt als een stabiel alternatief voor loopbruggen en platforms.

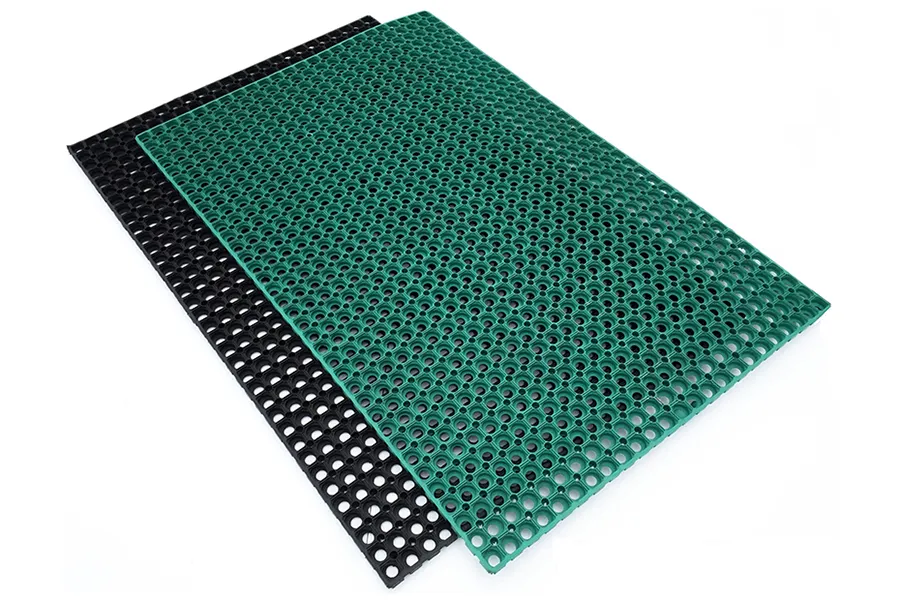

Verkrijgbaar in verschillende diktes en gegoten met een 3mm dikke massieve plaat om het gaas te sluiten.

Alle panelen zijn 3660mm x 1220mm en zijn verkrijgbaar in verschillende kleuren.

Snelst mogelijke bezorgtijd: Snelst mogelijke bezorgtijd: Tot 5 werkdagen

Isophtaal polyester vloerpanelen worden gebruikt voor toepassingen waar een hoge sterkte-gewichtsverhouding, niet-geleidbaarheid en corrosiebestendigheid vereist zijn. GRP Looprooster bevat ultramoderne ultraviolette inhibitoren om zonnedegradatie tegen te gaan wanneer geïnstalleerd in buitenruimtes.

GRP Looprooster wordt geschat tussen 50 en 100 jaar mee te gaan, afhankelijk van de omstandigheden, vanwege hun uiterst duurzame aard – dit komt door hun vermogen om zware werkomgevingen te weerstaan waar ze mogelijk veel gebruikt worden.

GRP is een waterdicht materiaal dat veel gebruikt wordt in de maritieme sector. Het kan omgevingen weerstaan waarin het regelmatig aan water wordt blootgesteld en behoudt daarbij hoge niveaus van slipweerstand.

GRP is ook bestand tegen UV-licht en zal niet verslechteren als gevolg van blootstelling aan UV-licht, waardoor het een ideaal product is om te kiezen waar dit een belangrijke factor is.

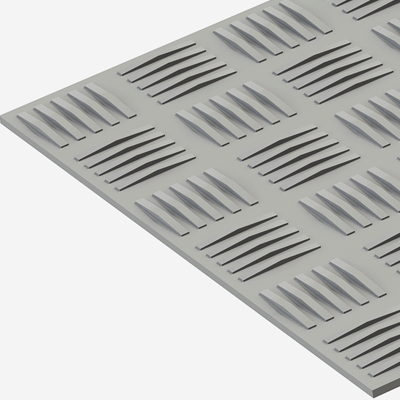

Voldoet aan nationale en internationaal erkende normen om verbeterde slipweerstand te garanderen.

Voordelen:

-

Materiaalsamenstelling:

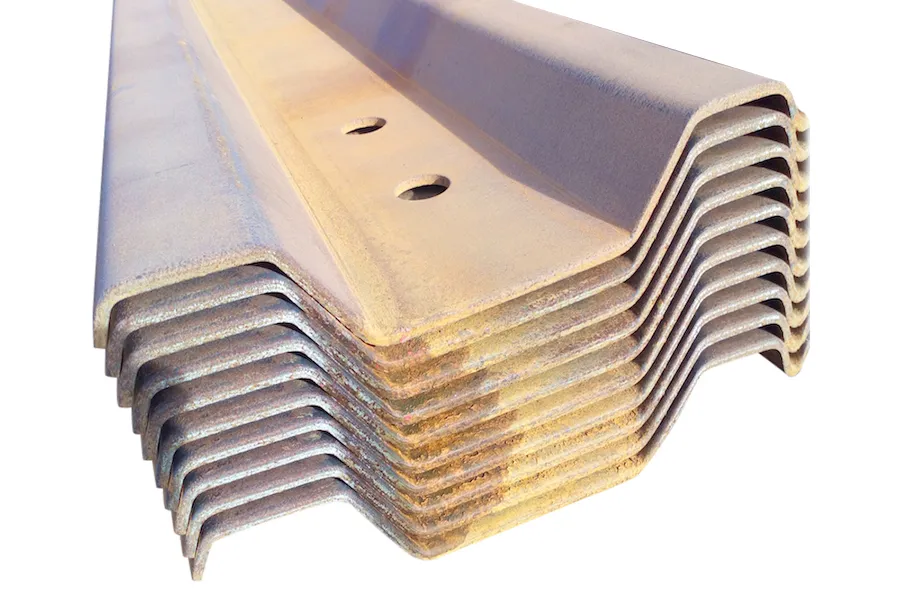

- Versterking: GRP looprooster bestaat uit glasvezelversterking ingebed in een harsmatrix, meestal polyester- of vinylesterhars.

- Oppervlaktecoating: Het bovenoppervlak van het rooster kan een getextureerde afwerking hebben voor slipweerstand, en de harsformulering kan worden aangepast voor specifieke omgevingsomstandigheden zoals UV-blootstelling of chemische weerstand.

-

Eigenschappen:

- Corrosiebestendigheid: GRP looprooster is zeer bestand tegen corrosie veroorzaakt door vocht, chemicaliën en zeewater, waardoor het ideaal is voor buitentoepassingen en maritieme toepassingen.

- Lichtgewicht: In vergelijking met traditionele materialen zoals staal, is GRP rooster lichtgewicht, wat transport, hantering en installatie vereenvoudigt.

- Hoge Sterkte: Ondanks zijn lichte aard biedt GRP looprooster indrukwekkende sterkte en draagvermogen, geschikt voor voetgangersverkeer.

- Niet-geleidend: GRP is niet-geleidend, wat elektrische isolatie en veiligheid biedt in omgevingen waar elektrische gevaren een zorg zijn.

- Brandweerstand: GRP rooster kan worden vervaardigd om te voldoen aan brandveiligheidsnormen, waarbij verschillende graden van brandweerstand worden geboden.

-

Toepassingen:

- Industriële Loopbruggen: Gebruikt in industriële faciliteiten voor verhoogde loopbruggen, kattenlopen en platforms waar corrosiebestendigheid en duurzaamheid cruciaal zijn.

- Maritieme en Offshore Platforms: GRP looprooster is gangbaar op dokken, pieren en offshore platforms vanwege zijn vermogen om zeewater en zware maritieme omgevingen te weerstaan.

- Commerciële Gebouwen: Ideaal voor voetgangersbruggen, mezzanine vloeren en gebouwexterieurs waar een lichtgewicht, onderhoudsarm vloermateriaal vereist is.

- Waterzuiveringsinstallaties: Veel gebruikt in waterzuiveringsinstallaties en afvalwaterfaciliteiten vanwege de weerstand tegen chemicaliën en vocht.

- Architecturaal: GRP rooster kan worden gebruikt in architecturale projecten voor decoratieve doeleinden of om innovatieve ontwerpen te creëren voor openbare ruimtes.

-

Voordelen:

- Duurzaamheid: Bestand tegen roest, corrosie en degradatie over tijd.

- Onderhoudsarm: Vereist minimale onderhoud vergeleken met traditionele materialen zoals staal.

- Eenvoudige Installatie: Lichtgewicht panelen zijn gemakkelijk te transporteren en te installeren.

- Aanpasbaar: Verkrijgbaar in verschillende kleuren, afmetingen en oppervlaktetexturen om aan verschillende projectvereisten te voldoen.

- Veiligheid: Antislipoppervlakken kunnen de veiligheid voor voetgangers verbeteren.

GRP looprooster biedt een veelzijdige en kosteneffectieve oplossing voor voetgangerspaden en platforms in een breed scala aan industrieën en omgevingen. De combinatie van sterkte, duurzaamheid en corrosiebestendigheid maakt het een voorkeurskeuze voor veel toepassingen waar traditionele materialen mogelijk niet goed presteren of onpraktisch zijn.

Heb je nog hulp nodig? Neem dan contact op met HERMEQ.

Neem contact op door te e-mailen naar sales@hermeq.nl of bel ons tussen 9:00 en 17:00 op +31 202417011

Nederlands

Nederlands Engels

Engels Bezoek HERMEQ Irlande

Bezoek HERMEQ Irlande Bezoek HERMEQ Frankrijk

Bezoek HERMEQ Frankrijk Bezoek HERMEQ DACH

Bezoek HERMEQ DACH